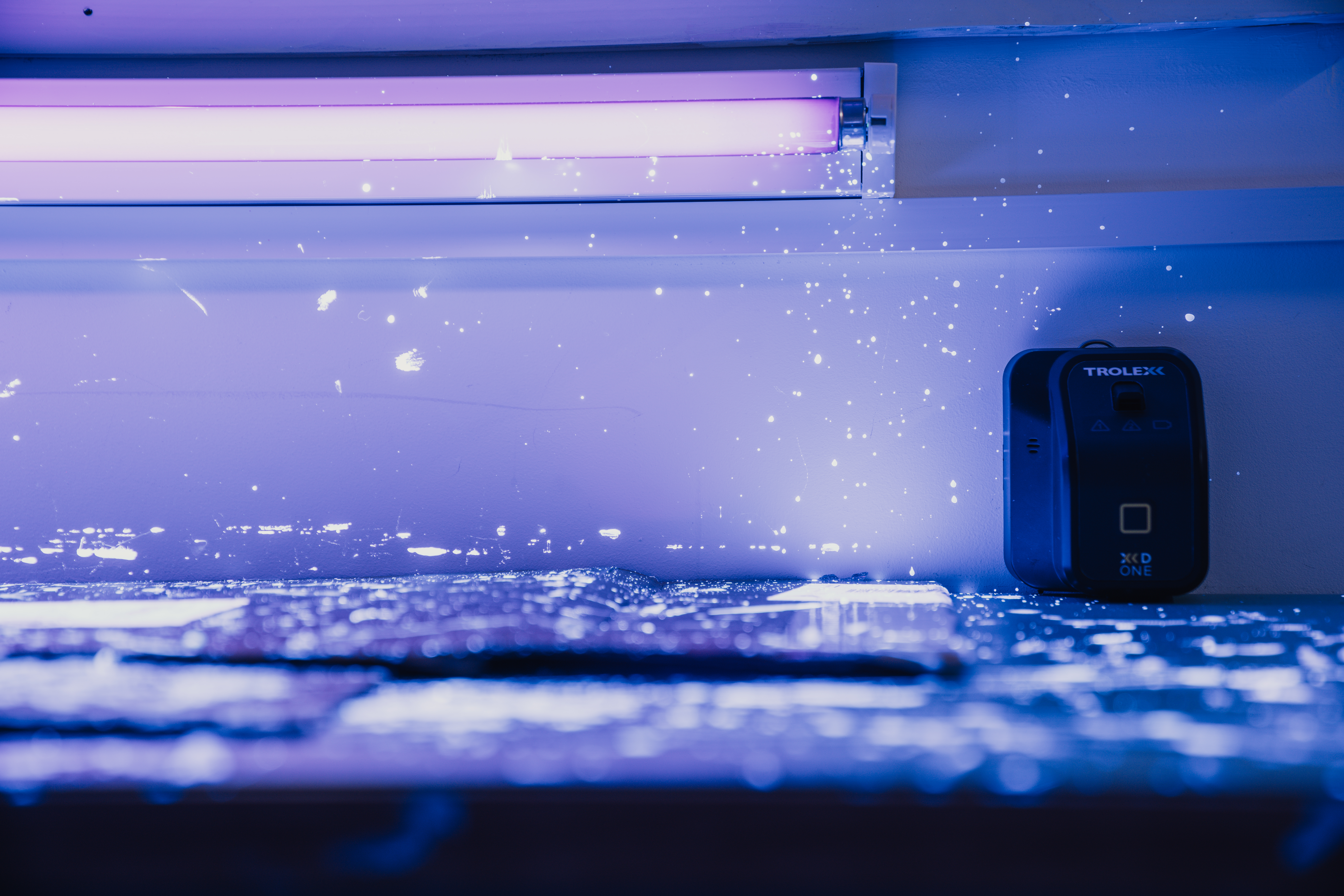

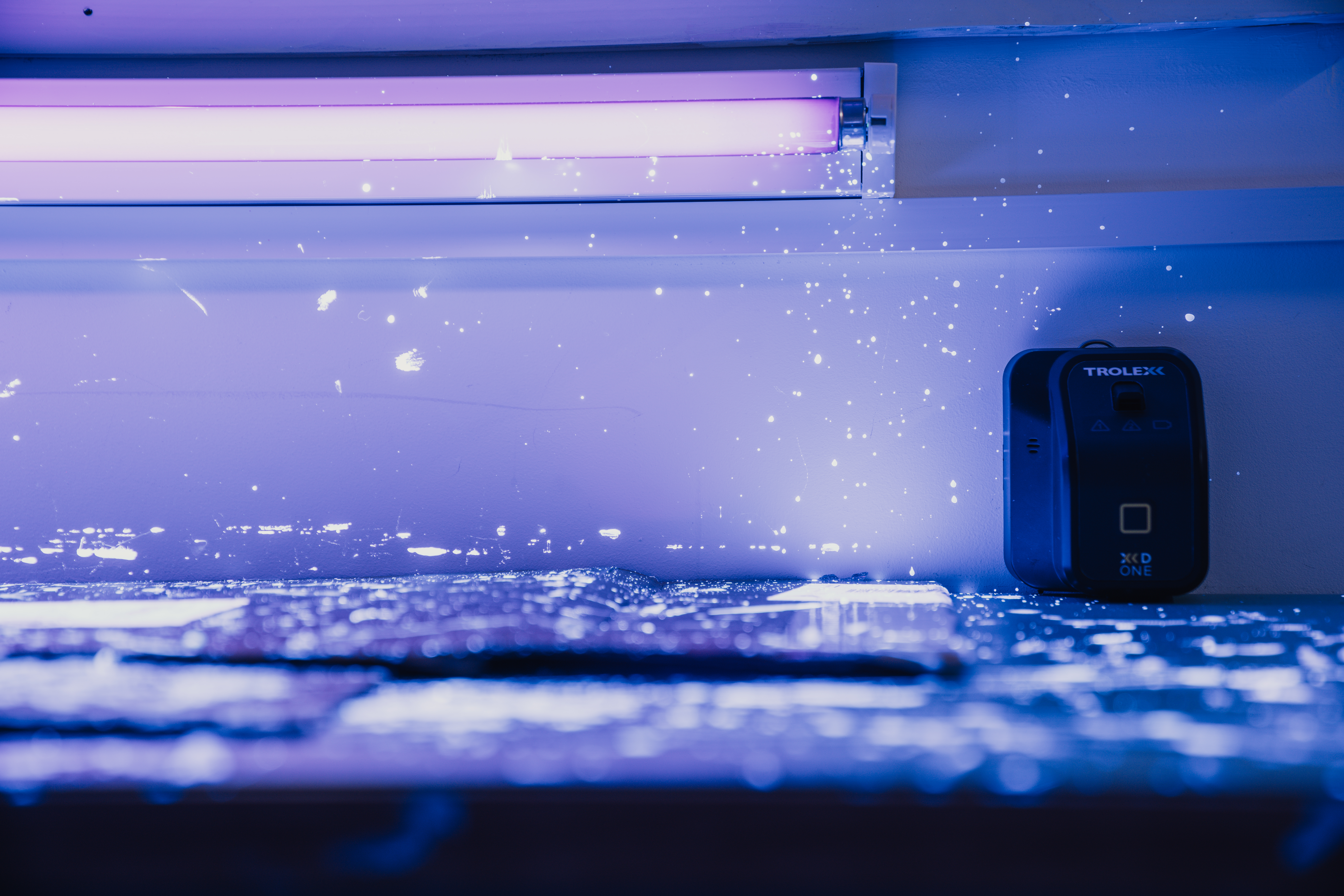

See why the world’s biggest mining and industrial corporations put Trolex equipment at the heart of their multi-billion dollar projects, when productivity, reputation and the health of their workforce depend on it.

Featured

Latest

Filter by:

See why the world’s biggest mining and industrial corporations put Trolex equipment at the heart of their multi-billion dollar projects, when productivity, reputation and the health of their workforce depend on it.

Filter by: